History

isol8 is developing the most advanced downhole alloy barrier technology.

isol8 was formed to exploit the benefits of alloy sealing technology in downhole well applications.

isol8 continues to lead downhole alloy seal innovation which represents a major advance in well integrity technology.

The journey began with relatively simple bismuth alloy seals, offering dependable sealing performance in demanding downhole environments.

Progressing further, metallurgically bonded alloy barriers (Fusion®) were developed to deliver permanent, high-strength seals directly bonded to the casing or formation.

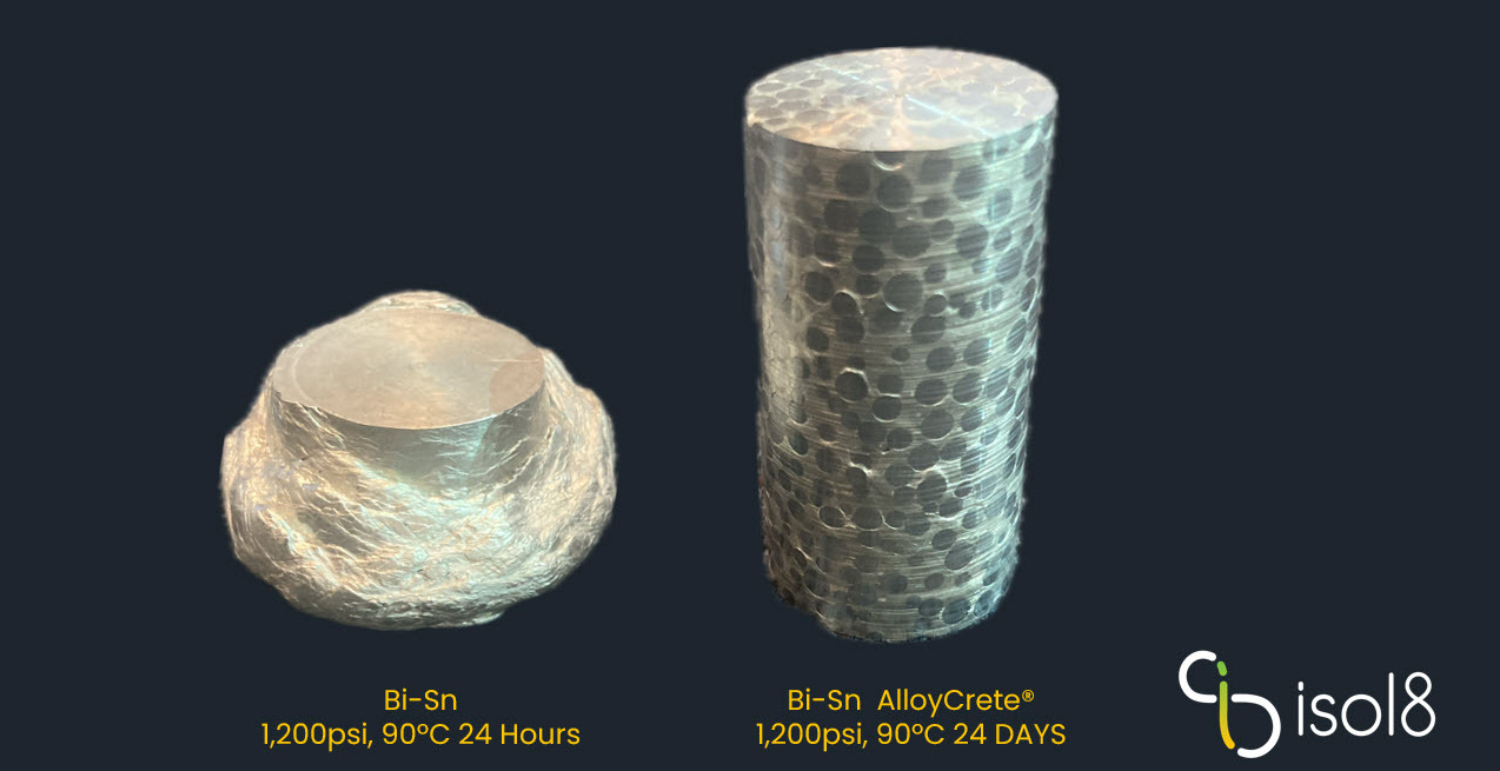

Just as concrete is stronger than cement, isol8's AlloyCrete® delivers the ultimate creep resistant barrier under pressure and temperature, to maximise the barrier's life expectancy.

The technology has now evolved beyond bismuth, incorporating advanced bonded alloy elements with enhanced mechanical and thermal properties.

Most recently, isol8 initiated the development of cold-set alloy elements, capable of forming seals without external heating. These have successfully completed 10,000 psi tests across slimline, conventional, and high-expansion element configurations.

Alloy sealing technology overcomes the weaknesses of cement and elastomers, providing gas-tight, durable isolation. Alloy seals also offer significant environmental benefits, reducing CO₂ emissions linked to cement and eliminating PFAS chemicals associated with elastomeric materials.

isol8 successfully qualified their first bonded alloy barrier in August 2020, only 18 months from kick-off. The first Fusion barrier was successfully deployed, set and tested offshore in the North Sea in October 2020. The world's first bonded alloy barrier designed, developed, tested, qualified and deployed in less than 2 years. A new standard in zero emission barriers has arrived.