Alloy Barriers

Alloy Barriers & Deployment Techniques

ALLOY BARRIERS - A downhole alloy seal is created by melting a low-melt-point alloy using a specialised heater. Once melted, the alloy flows into place and solidifies, forming a durable, pressure-resistant barrier for applications such as restoration of well integrity, production enhancement or plug-and-abandonment (P&A) operations. Annulus alloy barriers are considered as an alternative to cement, where a smaller volume of alloy can offer a superior long terms seal.

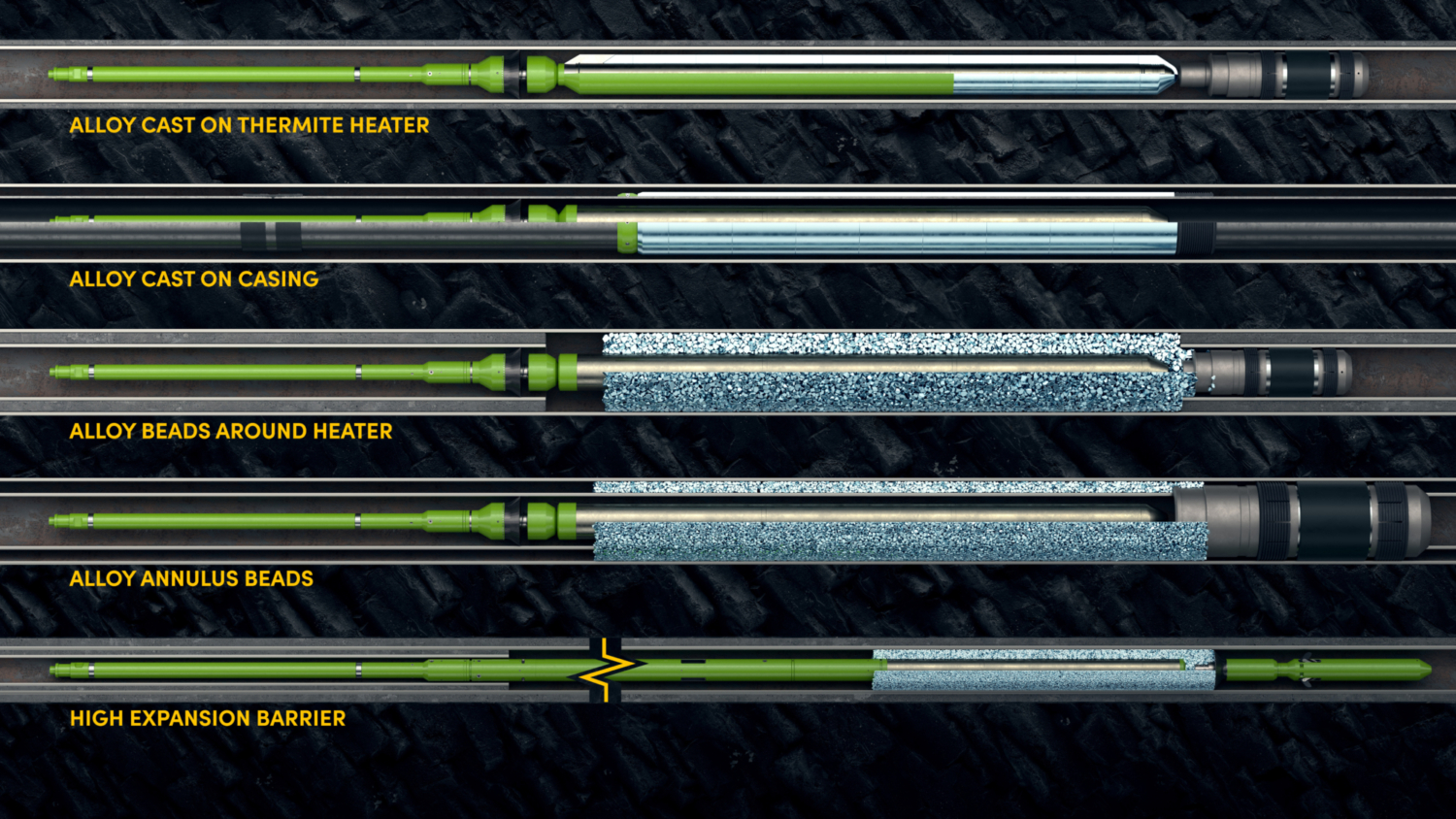

DEPLOYMENT TECHNIQUES - The choice of the most appropriate alloy deployment technique depends on wellbore geometry/restrictions, wellbore deviation, setting depth. These factors determine the size and placement of the heater needed to effectively melt the alloy and create a robust seal. By selecting the appropriate technique, operators can ensure effective heat management and optimised seal performance, even in complex or high-loss thermal environments.

The primary alloy barrier deployment techniques are shown below.

THERMITE HEATER REACTION VIDEO

Ensure your wells are protected with proven alloy barriers.

Share your project details and isol8 will align the right technology to your operational needs.