Alloy Barrier Single / Multi Annulus Isolation (P&A)

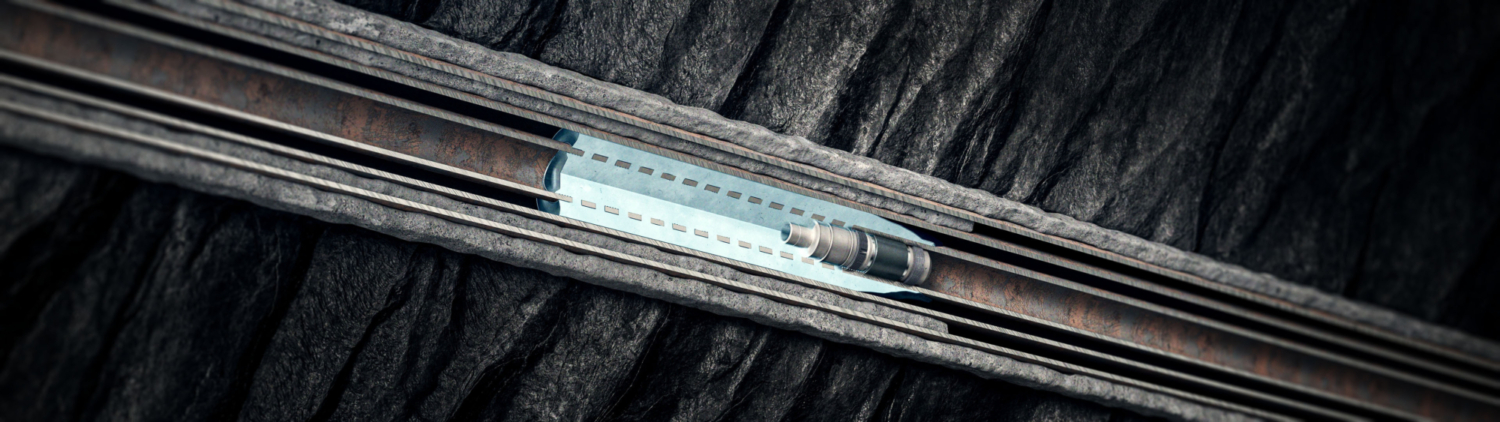

In larger diameter casings, an alloy barrier can be formed in multi-annuli through slots or perforations.

Thermite heaters are the most capable energy source to deliver the heat required for forming alloy barriers in the vast majority of wellbore geometries. Achieving uniform radial heat distribution is key in establishing a gas-tight seal. One of the factors influencing this is the natural upward movement of hot fluids within the wellbore, which can redirect thermal energy away from the intended zone. isol8’s patented convection deflector elegantly addresses this by preventing vertical fluid movement, concentrating heat exactly where it’s needed.

The result is maximum radial heat transfer into the surrounding casing, keeping the alloy molten at the outer boundary long enough to fully conform, bond, and deliver a high-integrity, long-lasting seal.